由安装于主机休下部的两台振动电机同步反向回转,使安装于期上的多层环状孔组成的主机体产生垂直振动与扭振,从页使由进料口进入的物料沿水平环状孔板自上层向下层连续跳跃运动

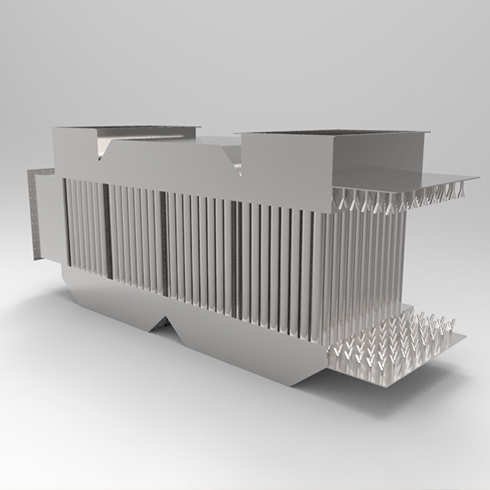

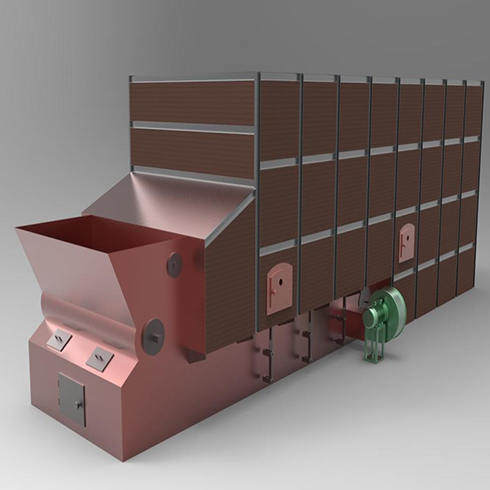

热烟气炉是一种产生高温烟气的机械链带式炉排炉,主要为烘干及提供200~1000℃高温净化烟气,炉内设有节能燃烧拱及高温净化室,热效率高达90%以上。燃料为煤或生物质燃料。

利用自身部分产品作燃料,无需额外添加燃料

利用自身部分产品作燃料,无需额外添加燃料

配有专用的木屑旋风喷烧炉和自动返料系统

配有专用的木屑旋风喷烧炉和自动返料系统

配有专用的木屑旋风喷烧炉和自动返料系统

配有专用的木屑旋风喷烧炉和自动返料系统

配有专用的木屑旋风喷烧炉和自动返料系统

配有专用的木屑旋风喷烧炉和自动返料系统

沈阳远大科技实业有限公司 创建于1997年,总部设于沈阳市辉山开发区,占地10000平方米下设一个科研机构——沈阳东大

干燥技术研究所,一个制造厂——辽宁远大干燥科技有限公司(位于铁岭高新区)。公司董事长兼总经理卢英林是东北大学资深教授、东北大学

干燥研究所前所长、辽宁省干燥技术学会理事长、国家级有突出贡献的干燥技术专家。

销售热线

销售热线

公司地址:辽宁省沈阳市沈北新区通顺街33甲

企业邮箱:yd@syydgz.com